A kwanakin baya, wasu kwastomomi sun rude a kan yadda ake gina kamfanin, da kuma yadda ake gina kamfanin, da kuma yadda ake gina kamfanin, yanzu bari mu gaya muku yadda ake gina ta.

Sashe na 1: Me za mu yi don ginin gine-gine?

Gudanar da Ayyukan Ayyuka

Tabbatar da buƙatar shayarwa

Da fari dai, za mu tabbatar da ƙarin cikakkun bayanai game da masana'antar ku, kamar nau'in giya, nau'in giya a kowace rana ko lokaci, plato na giya, lokacin fermentation, tsayin mashaya, da sauransu.

Na gaba za mu ba ku shawara bisa ga tabbacin ku da cikakkun bayanai.Za mu rattaba hannu kan kwangila bayan duka biyun sun yarda da sharuɗɗan haɗin gwiwa kuma mu sake tabbatar da tsari, farashi, shimfidawa, tsarin ƙira kafin sharuɗɗan.

1.3 Shiri yana aiki kafin samarwa

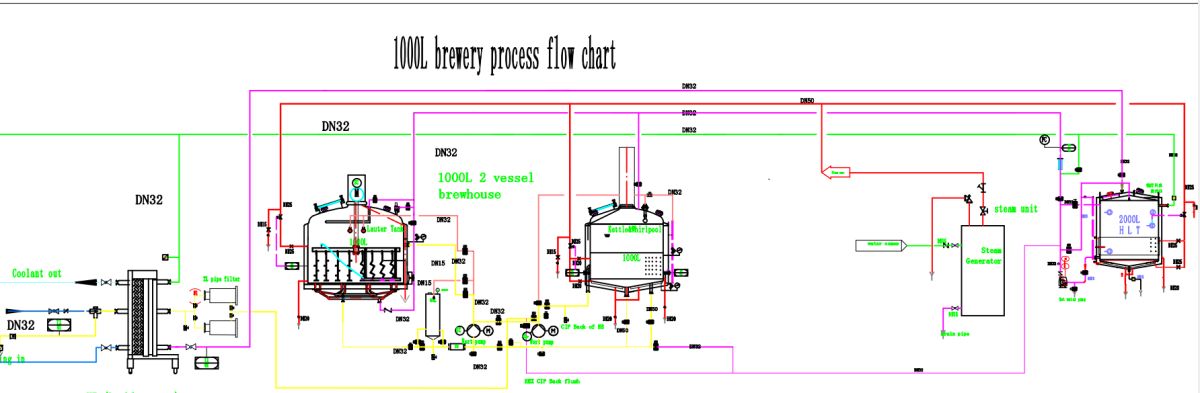

Sake duba duk shawarwarin, shimfidawa, jadawalin gudana kuma sake tabbatar da cikakkun bayanai na kayan aikin giya.

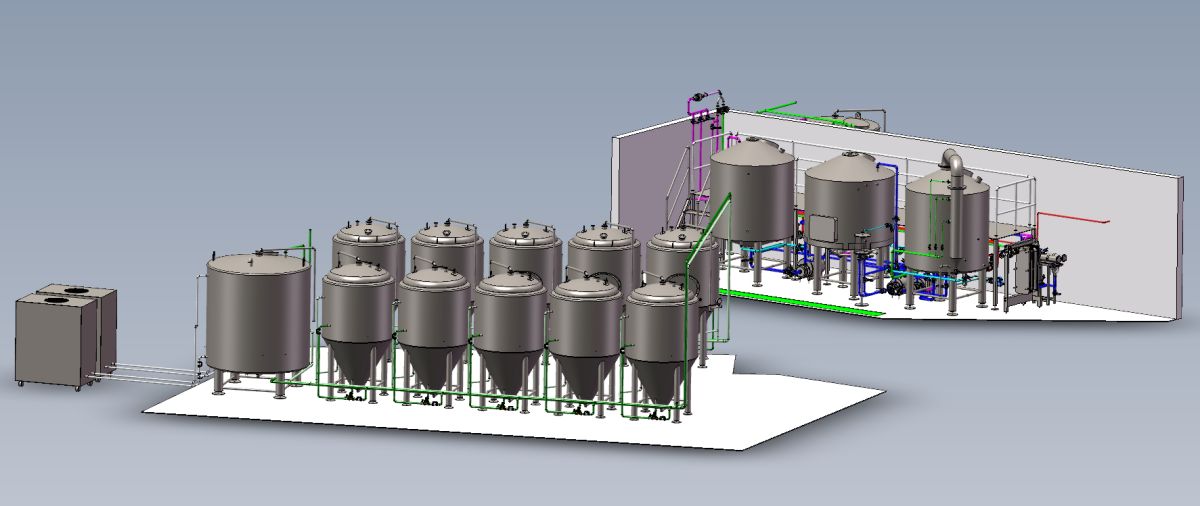

Kuma za a yi zanen tanki da samfurin brewery na 3D kuma za a ba ku damar tabbatarwa, za ku ga yadda girkin ku ya yi kama.

1.4 Shirye-shiryen Ramaterial

Yin ajiyar kayan abinci: za mu fara yin lissafin ɗanyen mataterial da kwanon abinci bisa ga zanen tanki da aka tabbatar, kuma sauran na'urorin haɗi za su yi ajiya, kamar mota, famfo, chillers, saboda waɗannan abubuwan suna buƙatar UL Certificated, wanda ke ɗaukar lokaci mai tsawo.

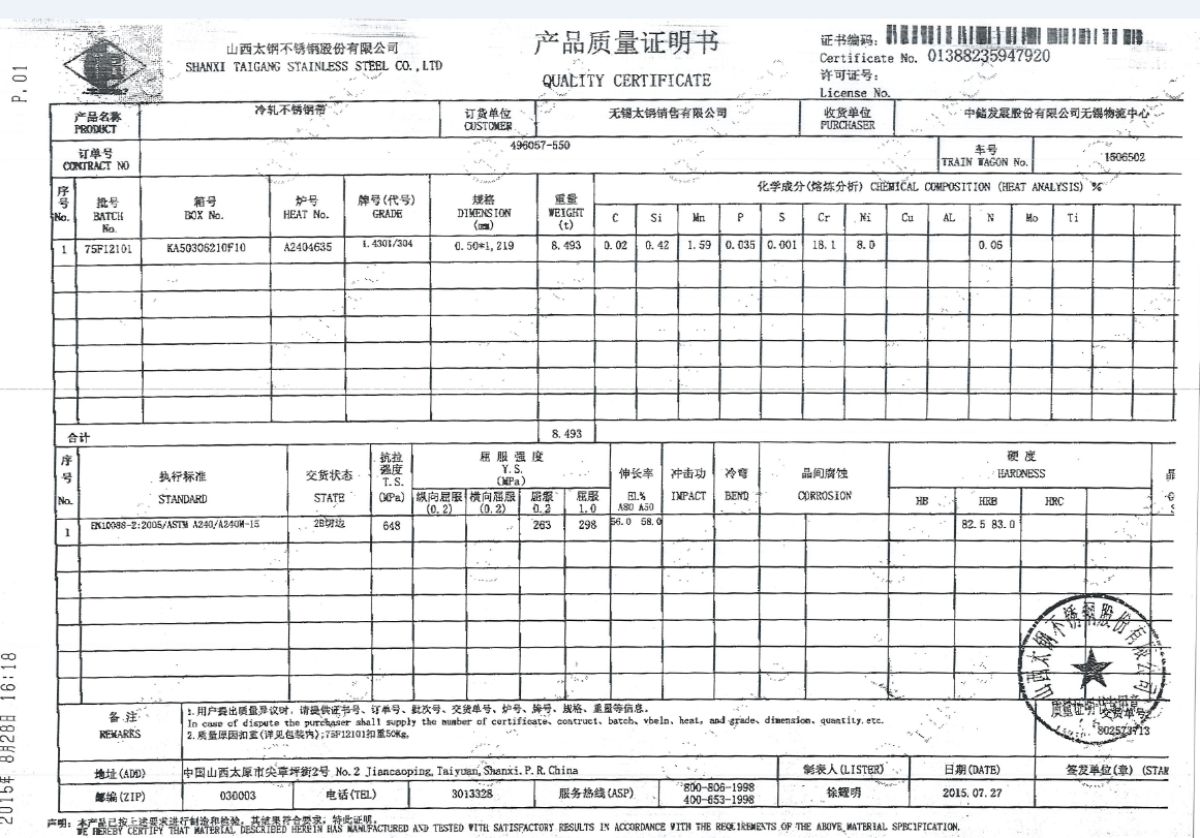

Lokacin da kayan ya isa masana'antar mu kuma yana shirye don samarwa, za mu aiko muku da takaddar kayanmu, kuma zaku ga kayan kayan, kauri, daidaitaccen da sauransu.

(Takaddar ingancin ingancin farantin SS don tunani.)

1.5 Fara samarwa

- Yanke kayan: Laser yankan, ingantaccen yankan, gefen lebur ba tare da burrs ba.

-Sheet karfe: Jiyya na faranti da sauran matakai daidai da samarwa.

-Taro: Welding da mazugi da Silinda tare, dimple sanyaya jaket, kafafu da sauran.

Welding rungumi dabi'ar TIG waldi hanya, wanda yana da mafi ingancin iska tightness kuma zai iya rage porosity na weld a lokacin waldi na matsa lamba jirgin ruwa.

-Polishing: Za a bi da saman ciki tare da goge goge na injina, da layin walda wanda aka goge zuwa bel don kyakkyawan gani.Bayan haka, tanki na ciki zai jiyya tare da fakitin fakitin, ƙarancin saman ciki shine 0.4um.

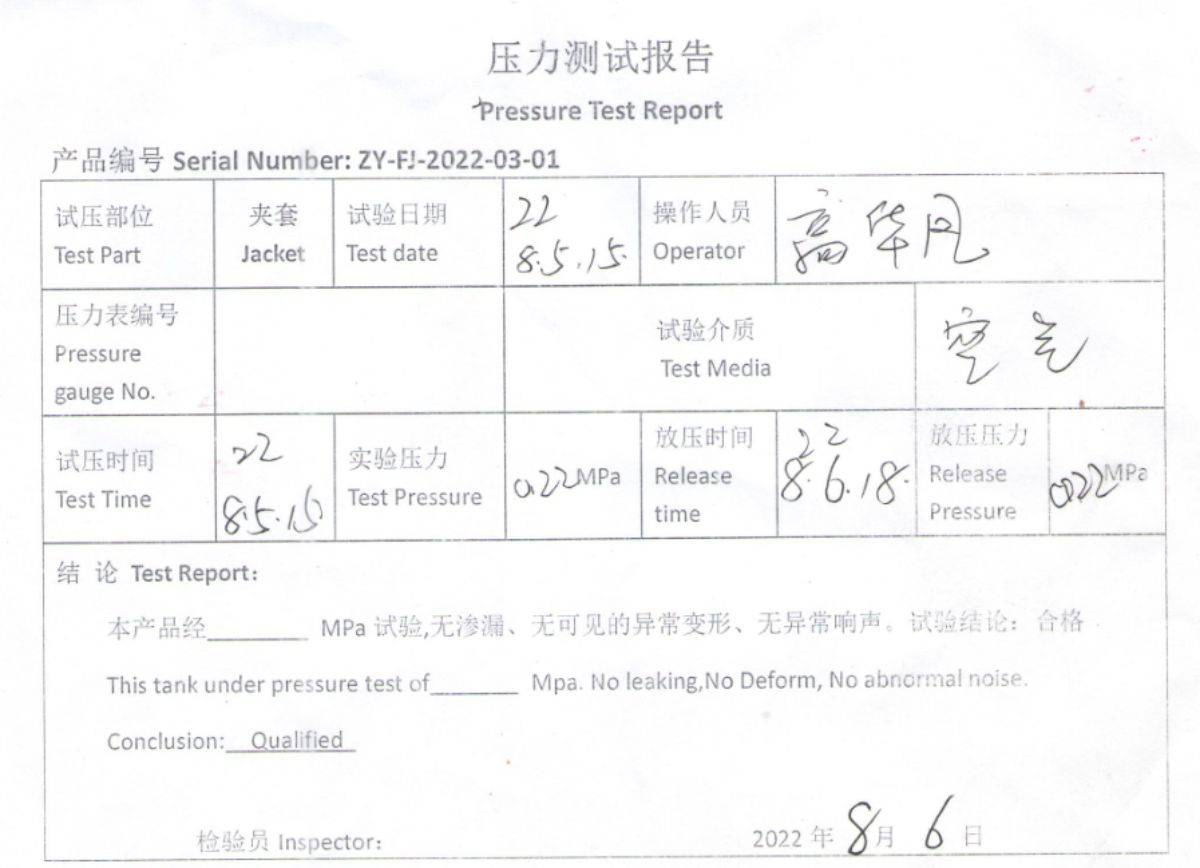

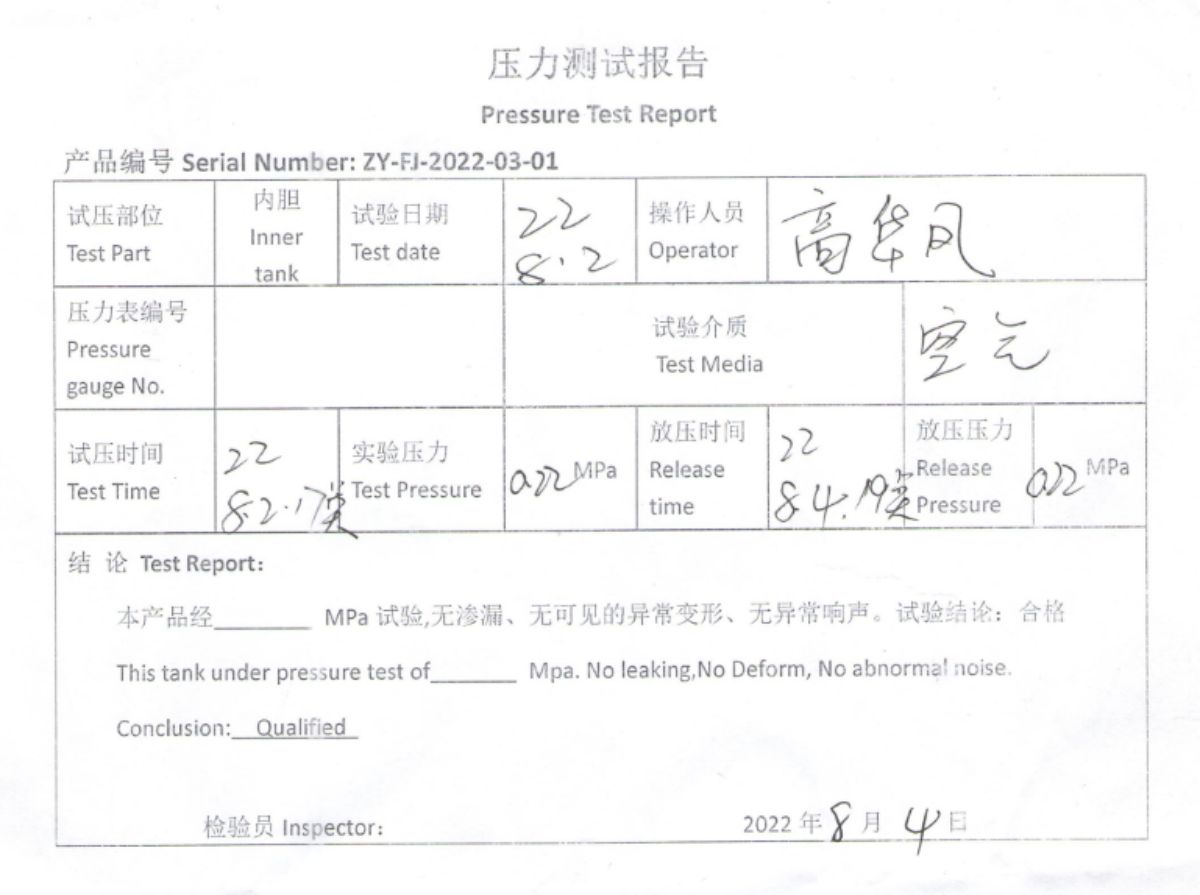

- Gwajin matsin lamba: Bayan kammala, ana gwada silinda da jaket ɗin ta hanyar ruwa.Gwajin gwaji na tanki na ciki shine 0.2-0.25mpa, kuma gwajin gwajin dimple jaket shine 0.2MPa.

-Bayanin samarwa: Za a bincika bayan kammala kowane tsari, kuma akwai katin zazzagewar tsari don tsari na gaba.Bayan kammala tankunan, sufeto namu zai duba cikakkun bayanai a karshe kuma ya sanar da taron taron mu don matsawa mataki na gaba.

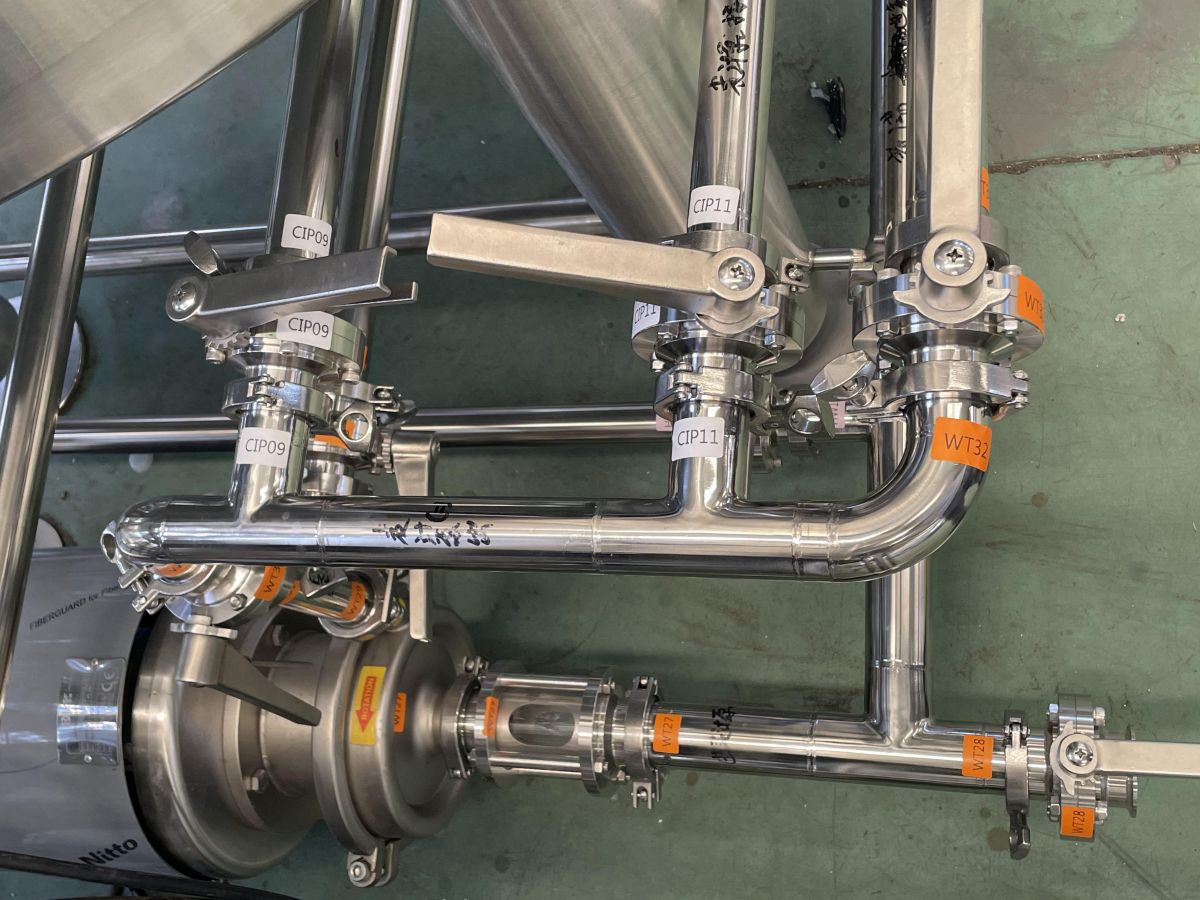

-Taron Bututun: Bututun Brewhouse za su haɗu bisa ga tsarin sarrafa bututun kuma za mu yi la'akari da bututun idan ya dace lokacin da ake yin bututun, da bututun glycol da aka riga an haɗa su kamar yadda aka tsara.

-Debugging: za mu haɗa ruwa da lantarki don yin aikin giya a cikin masana'antar mu.

Anan shine bidiyon da muka yi a baya don gwada tsarin mu.Pls duba shi:https://www.youtube.com/watch?v=wCud-bPueu0

-Package: Bayan gama gyarawa, za mu makala alamomi akan kowane haɗin gwiwa da bututu don sauƙin shigarwa a cikin rukunin yanar gizon.Kuma za a yi shi da fim ɗin Bubble da rigar yaƙi, da sauransu.

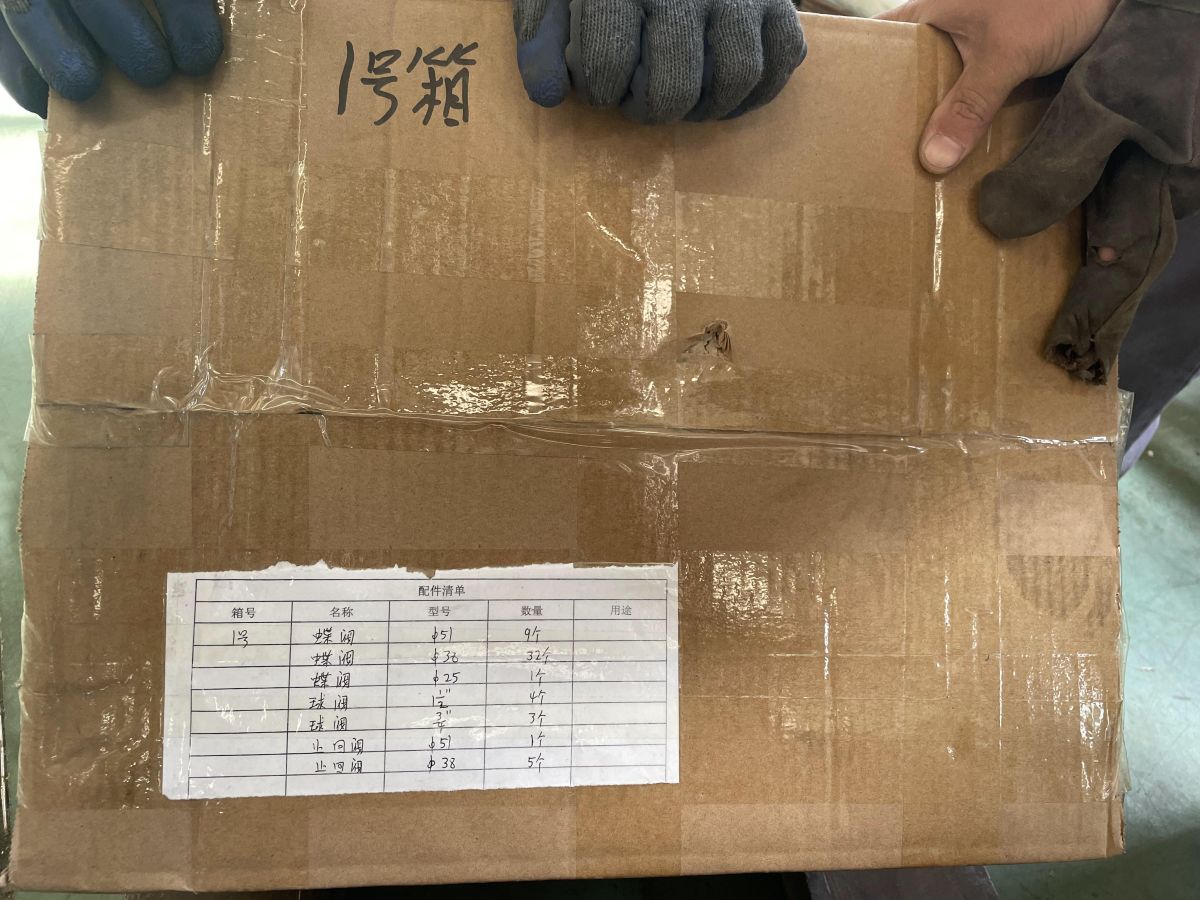

Za a nannade dukkan bawuloli da kayan aiki da filastik kunsa kuma a nannade tanki kotallafi bisa ga girman kayan aiki da girman kwantena.

-Loading da bayarwa: Za a ɗora kayan aikin bayan mun tabbatar da kwanan watan aikawa da kaya.Duk fakitin za a yi cikakken alamar abin da ke cikin na'urorin haɗi kuma aika abokin ciniki bayan bayarwa.

Sashe na 2: Me za mu yi don zayyana masana'anta?

2.1 Brewhouse: Ya dace sosai tare da buƙatar shayar ku.

Bangaren Brewhouse shine mafi mahimmancin sashi a cikin duka masana'anta, wanda ke da alaƙa kai tsaye tare da ingancin wort da giya.Dole ne ƙirar ƙira ta bi daidai girke-girke na girkin ku, misali matsakaicin nauyin giya / plato.Tabbatar cewa za a iya gama aikin Mash ko aikin lauter a cikin lokacin da ya dace.

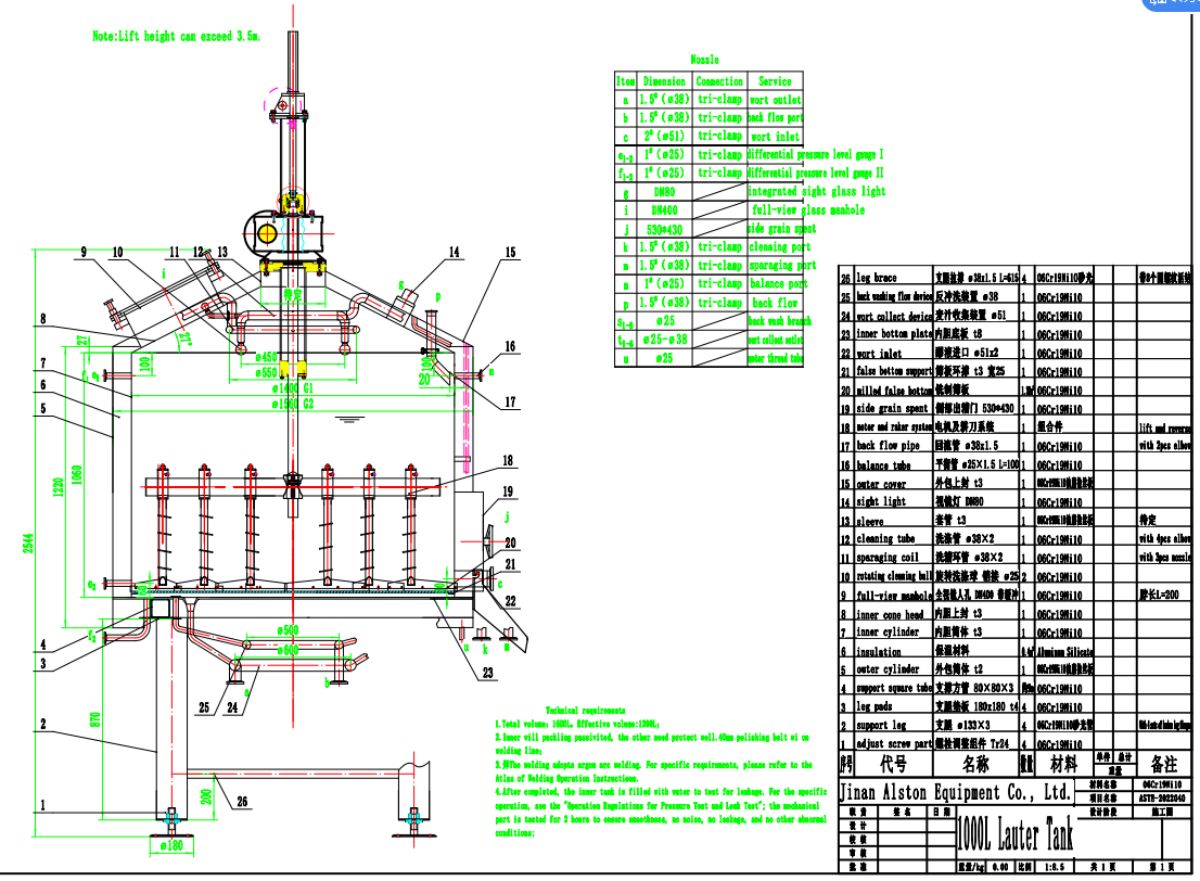

Lauter tank: Misali 1000L Brewery, The diamita na lauter tank ne 1400mm, a lokacin da wort ne 13.5 digiri, da malt ciyar adadin ne 220KG, da kayan aiki ta yin amfani da yadda ya dace ne ga 75%, da kuma kauri daga cikin hatsi Layer ne 290mm;Lokacin da wort shine plato 16, adadin ciyarwa shine 260KG, girman tanki yana amfani da 80%, kuma kauri ga gadon hatsi shine 340mm.Wannan shine don tabbatar da kauri daga cikin tacewa ya dace da buƙatun buƙatun, baya shafar saurin tacewa kuma yana tabbatar da ingancin samarwa.Ƙarshe don inganta fitarwa kowane lokaci naúrar ta hanyar rage lokacin tacewa.

Kettle Boiling: Tsarin ƙarar kettle ya dogara ne akan 1360L wort don tafasa, kuma ƙarar amfani shine 65%.Saboda concetration na wort ya fi girma a Amurka, nau'in zai yi yawa lokacin tafasa.Don hana kumfa da ke zubewa daga kettle a lokacin aikin tafasa, muna amfani da aikin tilastawa wurare dabam dabam don inganta yawan ƙawancen don tabbatar da yawan ƙawancen ya kasance 8-10% kuma inganta ƙarfin tafasa.A tilasta wurare dabam dabam tare da kettle taimaka ƙara evaporation, da DMS halin da ake ciki da abun ciki a cikin 30PPM, shi zai rage zafi loading da kuma tabbatar da kwanciyar hankali na wort chroma da kuma guje wa wort Maillard dauki.

2.2 Ƙarƙashin amfani da makamashi a cikin masana'anta

Tsarin Condensor: Kettle ɗin tafasa yana ɗaukar tsarin dawo da tururi, zai taimaka wajen haɓaka dawo da ruwa da adana ruwa da amfani da wutar lantarki a cikin masana'antar giya gabaɗaya.The dawo da ruwan zafi zafin jiki a kusa da 85 ℃, da kuma ruwan zafi dawo da damar a 150L ga kowane tsari;Wannan yana nufin zai adana wutar lantarki 18kw a kowane tsari na zafin ruwa daga 25-85 ℃.

Wort mai sanyaya: Wurin musayar zafi na wort yana ƙididdigewa ta hanyar aikin shayarwa kuma gama aikin sanyaya cikin mintuna 30-40, da zafin ruwan zafi a 85 ℃ bayan musayar heax, ƙimar musayar zafi fiye da 95%.Don haka, za mu tabbatar da matsakaicin dawo da makamashi da ƙananan farashin samarwa.

2.3 Sauƙaƙan shayarwa da rage kiyayewa a cikin tsarin shayarwa

An daidaita nau'i-nau'i biyu, idan abokin ciniki ya sha giya mai yawa.Don haka muna kawo garanti mai kyau akan farantin zafi, wanda shine mafi wahala ga tsaftacewa.

Dual famfo ya zama dole don naúrar glycol, don kyakkyawan garanti lokacin da akwai buƙatar kiyayewa, kowane famfo na iya canzawa cikin sauƙi don ci gaba da samarwa.

An daidaita chiller dual, tare da manufa iri ɗaya kamar famfo glycol.

Glycol famfo ya yi amfani da famfon matsa lamba akai-akai kuma yana kiyaye matsa lamba iri ɗaya a cikin bututun glycol gabaɗaya, yana kare bawul ɗin soleniod da faɗaɗa rayuwar amfani.

Duk waɗannan cikakkun bayanai shine don ƙarin aikin kwanciyar hankali a cikin aikin masana'anta gabaɗaya, kuma suna kawo muku kyakkyawan gogewa a cikin aikin ƙira.

Sashe na 3: Menene lokacin shiri da ake buƙata?

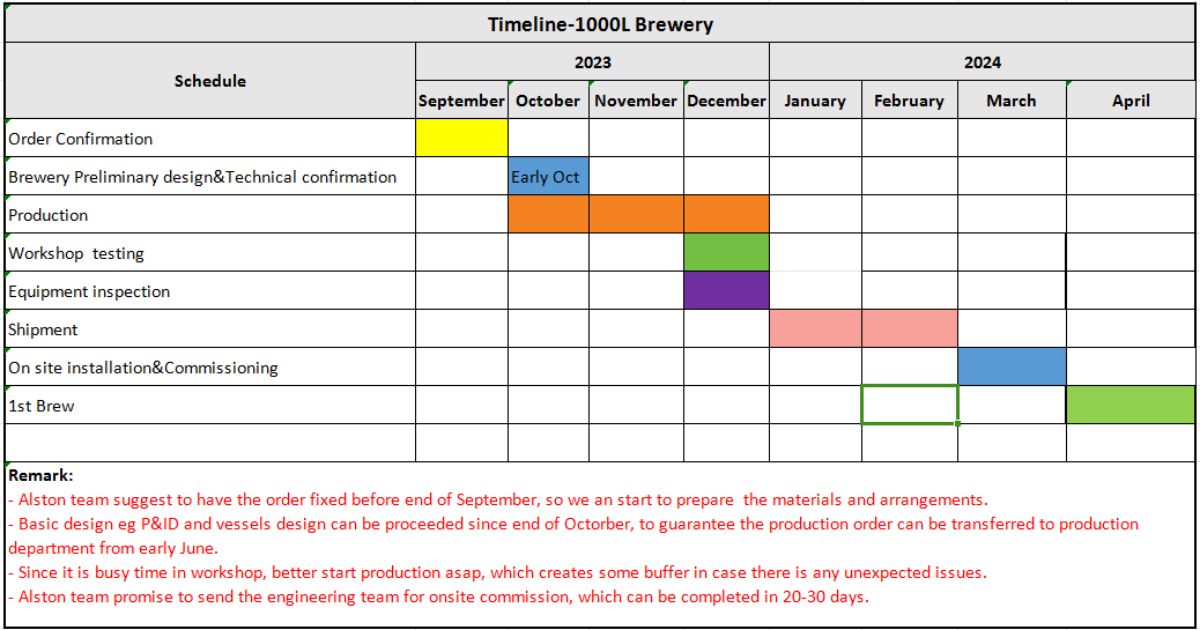

Yanzu don share tsarin tsari, mun sanya tsarin tsarin aikin giya, pls ganin haka.

Da fatan za mu iya taimaka muku don gina ingantaccen masana'anta a cikin shirin ku.

A ƙarshe, muna fatan yin aiki tare da ku nan ba da jimawa ba.Ta wannan haɗin gwiwar, za ku ji hidimarmu da ƙimarmu.Ba wai kawai ya kamata mu gina muku ingantaccen masana'anta ba, har ila yau, mun fi mayar da hankali kan kafa dangantakar hadin gwiwa ta dogon lokaci don cimma nasarar nasara a tsakanin bangarorin biyu.

Na gode da lokacin ku.

Yi murna!

Lokacin aikawa: Satumba 18-2023