Daga farko zuwa ƙarshe, aikin shayarwa yana farawa kuma yana ƙarewa a cikin tukunyar dusar ƙanƙara.

Ana shigar da zafin ruwa da ake so yajin aiki da ƙarar a cikin cibiyar umarni.PLC ta atomatik tana cika tanki zuwa matakin da ya dace kuma mai ƙone mu yana kula da yanayin ruwan yajin da muka shiga.Kafin ruwa ya shiga cikin kettle, ya wuce ta 1 pad filter, carbon block filters 2 da kuma tukunyar ruwa maras tanki.

● Da zarar kwanon dusar ƙanƙara ya cika, sai mu kunna mahaɗin kuma a zuba hatsin da aka niƙa a cikin ruwa ta amfani da bokitin gallon 20.Da zarar an gauraya hatsi da ruwa sosai, za a zauna a cikin wannan tanki na tsawon sa'o'i 1.5-3 inda za a yi jerin matakan zafin jiki har sai an wargaza sitaci da ke cikin hatsin zuwa sukari.

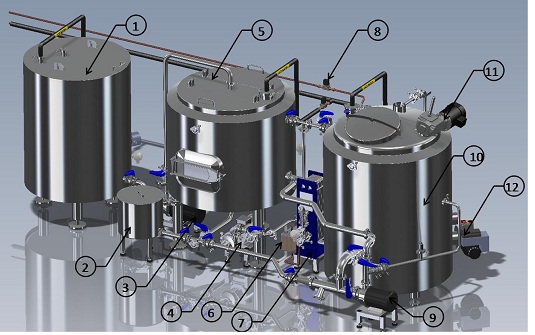

3bbl 5bbl Bayanin Tsarin Kayan Aikin Kaya

1. RUWAN RUWAN ZAFI

2. KYAUTA LAUTERING

3. SPARGE PUMP

4. WORT PUMP

5. LAUTER TUN

6. GLYCOL Pre-Chiller

7. WORT CHILLER

8. KWALLON RUWA

9. GASKIYAR TSARO/ GUDA

10. MASH TUN / KETTLE

11. MOTA MAI HADA

12. WUTA WUTA

● Sai a zuba cikakkar dusar a cikin Lauter Tun inda za'a datse tsutsar zaki daga dusar yayin da ake fesa ruwan zafi a saman hadin.Ana kiran wannan tsari sparging.Don kiyaye gadon hatsi daga ƙaddamarwa, an zubar da wort a cikin kyautar lautering.Wannan ƙaramin tanki ne tsakanin tunin lauter da famfo wanda ke hana famfo daga jan wort da sauri fiye da yadda zai iya zubar da ruwa.Daga kyautar lautering, ana juyar da wort zuwa tankin da aka keɓe, yayin da rabin na biyu na batch ɗin ana niƙa a cikin kwanon dusar ƙanƙara.

● Da zarar mash #2 (yana bin tsari iri ɗaya kamar na #1) an canja shi zuwa ga tungar da aka tsaftace, ana zub da tsumman da ke cikin tanki a cikin kwanon dusar ƙanƙara don tafasa.A lokacin tafasa hops ana kara da shi.Tsawon tsayin daka ga tafasa zai fitar da ɗanɗano mai ɗaci yayin da gajeriyar fallasa zai ba da damar ƙarin ƙamshi a cikin ƙãre samfurin.

● Bayan tafasa shine guguwa.A lokacin guguwar, ana fitar da wort daga cikin kettle kuma a mayar da shi gefe, yana tanƙwara zuwa tanki.Tasirin guguwa yana haifar da ɓangarorin hop don tattarawa a tsakiya yayin da ake fitar da madaidaicin wort a waje.Bayan guguwar, ana barin kettle ya daidaita kuma duk barbashi da aka tattara a tsakiyar tudun suna nutsewa zuwa ƙasa.Tare da barbashi a tsakiya, bayyanannun wort da aka shirya don yin famfo zuwa mai musayar zafi.

● Ana fitar da ma'auni mai tsabta ta hanyar musanya mai zafi wanda ke ɗaukar zafin jiki daga 200+ deg F zuwa zafin jiki na yisti - 70-75 ° F. Mai musayar zafi yana aiki a cikin hanyar da aka zubar da wort ta cikin jerin faranti na bakin ciki yayin sanyi. Ana zubar da ruwa ta jerin faranti na makwabta, yana barin zafi daga wort ya wuce ta cikin farantin kuma cikin ruwan sanyi.Tun da ruwan mu na ƙasa bai fi zafin zafin da muke nufi ba a wasu lokuta a lokacin bazara, muna buƙatar fara sanyaya ruwan sanyi.Ana yin haka ta hanyar wucewa da ruwa ta hanyar pre-Chiller wanda ke amfani da glycol mai sake zagaye a 28 deg F. Wannan kuma yana rage yawan ruwan da muke amfani da shi.

● Yayin da tsutsotsin ke cika fermentor, ana jefa yisti kuma an rufe man hanyan tanki.Bayan sa'o'i 1-2, fermentor yana sanyi zuwa yanayin farawanmu - tsakanin digiri 58-68 dangane da giya.A lokacin fermentation, yisti yana cinye sukari a cikin wort kuma yana fitar da CO2, barasa da sauran abubuwan dandano.Zuwa ƙarshen fermentation, an haɗa wani mai sarrafa na musamman mai suna Spundapparat zuwa tanki don kama sauran CO2 a cikin giya.Wannan a zahiri yana carbonates giya kuma yana ba shi kyakkyawan kai mai santsi.

● Da zarar aikin fermentation ya daina, an kwantar da tanki zuwa kimanin 35 ° F. Wannan yana taimakawa yisti a cikin dakatarwa ya fadi zuwa kasan tanki don girbi na gaba.Lokacin yanayin sanyi kuma yana ba da damar dandano na giya don girma da daidaitawa.

● Da zarar an gama shan giya, sai a ajiye ta a aika zuwa mashaya, gidajen cin abinci da wuraren cin abinci.

Lokacin aikawa: Agusta-15-2023